Site Visit with Accenture & City Colleges of Chicago’s Daley College

Here at Lumity, we see time and again that getting young people out of the classroom and into real world STEM experiences ignites their enthusiasm and helps them see the possibilities for their future. The recent site visit by Lumity students from Thornwood High School to City Colleges of Chicago’s Manufacturing, Technology, and Engineering Center at Daley College exemplifies how powerful site visits are for all involved.

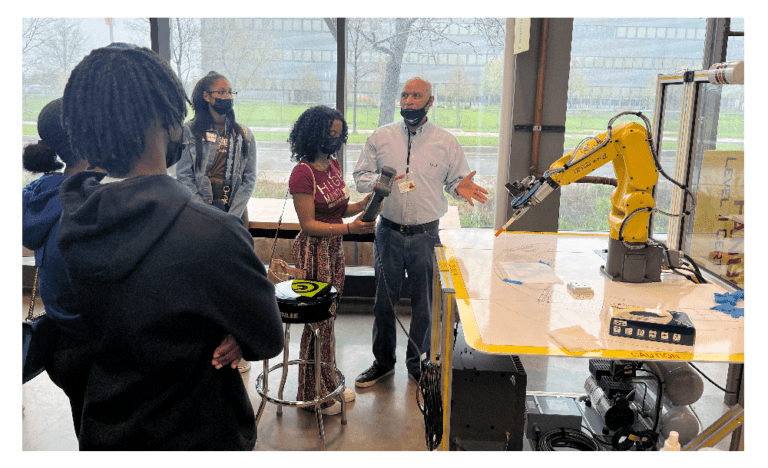

“We purposefully design our career site visits with partners so that our students have an intentional STEM career experience, and learn what they need to do—the types of courses they need to take or certifications that are necessary—to prepare for these jobs,” explains Cynthia Saucedo, Director of STEM Career Prep. “The hands-on nature of Daley’s machine lab plus an introduction to the college’s offerings was a perfect combination of a college-career experience.”

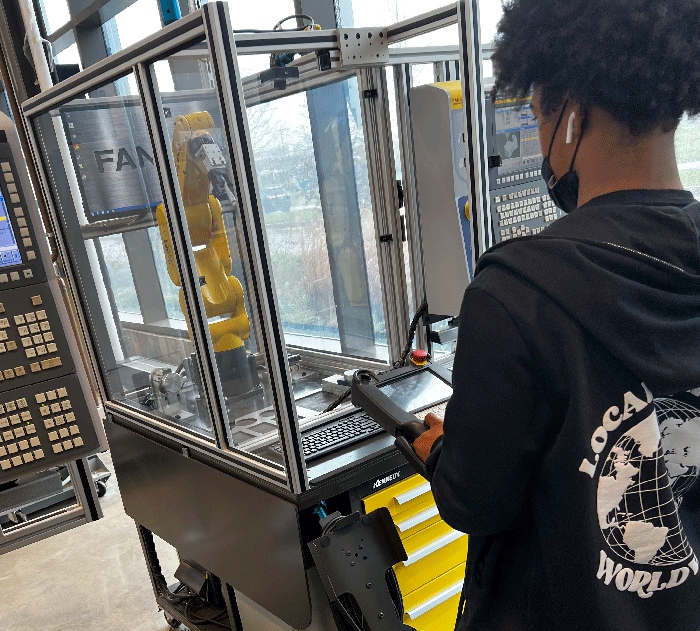

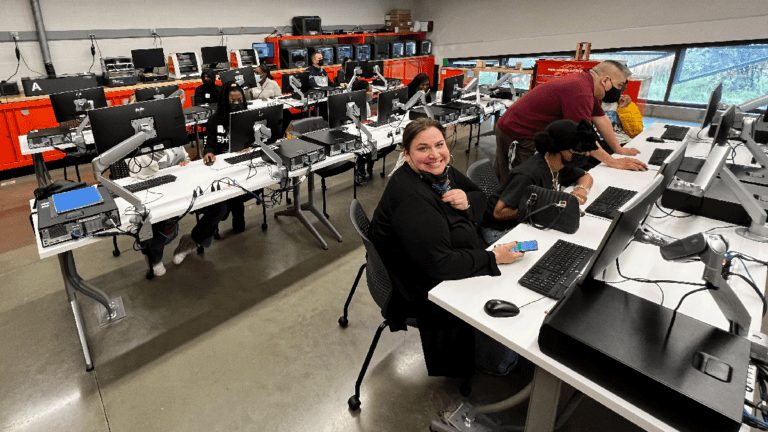

Thanks to Accenture’s support and our Daley College hosts, Lumity students spent a full day participating in the manufacturing process—from design to production—and connecting their experience to college courses and future career opportunities.

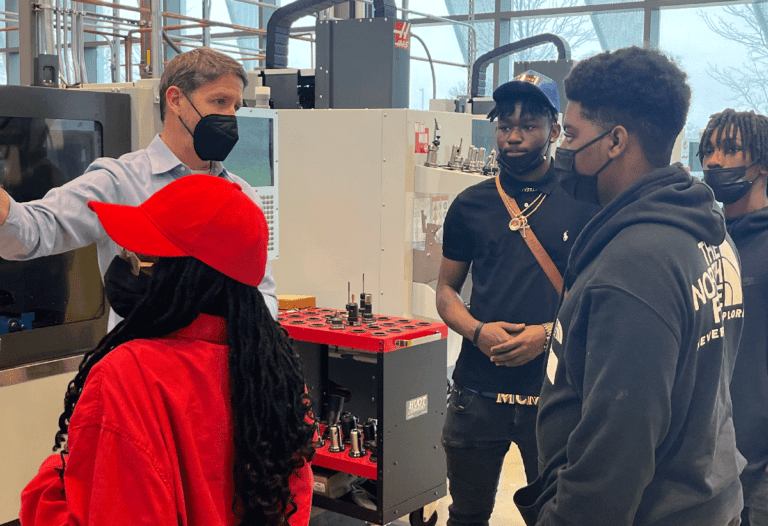

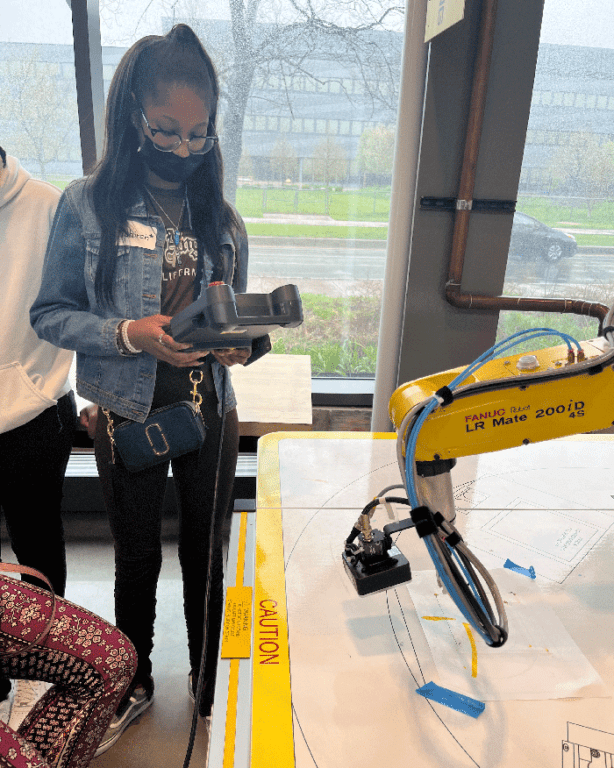

Working with the Dean of Advanced Manufacturing David Girzadas, Manufacturing Professor Juan Martinez, and Manufacturing Professor Charles Thompson, Lumity students were introduced to computer-aided design, mechatronics, and CNC machining. They then took on their own project using software to customize their school logo and a laser cutting machine to produce a wood replicable of their unique design.

“The Lumity students were engaged, attentive, and had good questions every step of the way,” noted Dean Girzadas. “We had them begin in the same way we work with our college students—by learning the cycle of manufacturing on a small, safe, approachable scale to then prepare for large equipment. Students were working in teams, learning how to adjust their design to fit technical capabilities, and then adjusting again if their product didn’t turn out the way they expected.”

“It was really fun to watch how the students responded, and interesting to see which students became really engaged and excited about their project,” adds Dean Girzadas. “You could see the extra effort the students were putting into their design and just knew they were getting it.”